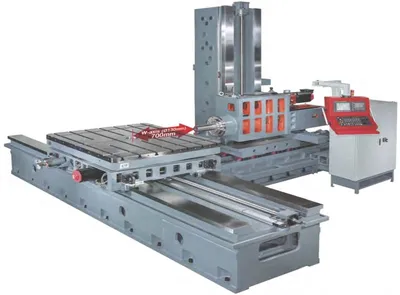

4.33" New Maxcut / Uchine CNC Horizontal Boring Mill

RIGID & STABLE CONSTRUCTION

All structural components are manufactured from high quality cast iron (FC30)

tempered and stress relieved.

T-SHAPE BASE

The T-shape base construction allows the machine to be equipped with various

table types. The A-axis slideways are

supported by a double wall cage shape construction for ultra-high rigidity.

GUIDE WAYS

Box ways on the X and Y-axes and Schneeberger roller type linear guide ways

featuring 12 blocks - on the Z-axis.

FINITE ELEMENTS ANALYSIS

The major structural components are designed with Finite Element Analysis

software to simulate stress/strain conditions

Control Fagor 8065

MACHINE SPECIFICATIONS:

UBM-11032RT /UBM-11042RT

Rotary Table

Table size 55.1" x 62.9"

Maximum load capacity with.............................0.001 Degree positioning 12000kg

Maximum load capacity with B-axis contouring...........10000kg

Minimum indexing increment.............................0.001 Degree

Travel

X-axis.................................................125.9"

Y-axis.................................................70.8"

Z-axis.................................................66.9"

W-axis.................................................19.68"

Spindle

Diameter...............................................4.33"

Taper CAT..............................................#50

Speed range from.......................................10 to 4000 rpm

Maximum power..........................................20.1/ 24.8 Hp.

Distances

Spindle center to table-top from.......................0 to 70.86"

Spindle nose to table center from......................0 to 86.6"

Height from ground to table surface....................48.6"

Feed Rates

Rapid X/Y/Z/W axis.....................................393 Inch per minute

Cutting X/Y/Z/W axis...................................196 Inch per minute

Minimum increment......................................0.0000393"

Automatic Tool Changer

Number of tools........................................60

Tool change time.......................................15 seconds

Maximum tool diameter with full adjacent pocket........4.921"

Maximum tool diameter with empty adjacent pocket.......9.842"

Maximum tool length....................................15.74"

Maximum tool weight....................................25kg

Coolant + Lubrication

Coolant tank capacity..................................105.6 Gallons

Hydraulic tank capacity................................21.133 Gallons

Lubrication tank capacity..............................2.1 Gallons

Miscellaneous

Power required.........................................55kVa

Pressurized air........................................13.2 Lbs.

Machine weight.........................................66,138 Lbs.

C3 Double Nuts High Class Precision

Ball Screws Fitted.....................................Yes

Table Load For Indexing And Positioning................13,000 Lbs.

Operator Manuals.......................................Yes

Machining Leveling Pads................................Yes

Air Conditioner........................................Yes

EMC....................................................Yes

Safety Module..........................................Yes

Work Lamp..............................................Yes

RS 232.................................................Yes

Heat Exchanger.........................................Yes

Auto Lubrication System................................Yes

Hydraulic System.......................................Yes

Coolant................................................Yes

Chip Auger For Table & Chip Conveyor...................Yes

Table Guards For CTS System............................Yes

Auto Power Off.........................................Yes

Telescopic Way Cover For Sub Supporter Guideways.......Yes

Table Guards Around Table..............................Yes

Coolant Thru Spindle 300 PSI...........................Yes

Box Ways...............................................X & Y Axis

Featuring 12 Blocks....................................Z Axis

Linear Scales..........................................X, Y, Z, Axis

Electric And Wiring Preparation For CTS................Yes

Spindle Oil Cooler.....................................Yes

Safeguarding Located At Rear Of Column.................Yes

STANDARD & OPTIONAL EQUIPMENT INCLUDED

Fagor 8065 control

Linear scales on X/Y/Z axes

Through spindle coolant system

Renishaw RMP60 + RTS wireless tool / work measuring probe system

Full enclosure, chip/splash guard

Spindle oil cooler

Automatic power off

Coolant system

Lubrication system

Alarm light

Work light

Manual pulse generator (mpg = electronic hand wheel)

RS232C interface

USB interface

Heat exchanger

Chip conveyor + cart

Leveling bolts + pads

Toolbox

Operation manual, control manual, circuit diagram

Machine inspection list

Extension sleeve

OPTIONAL EQUIPMENT

2000 x 1600mm Table, 12 Ton load capacity,

0.001° positioning: US...............................$12,900

Manual 90° Milling Head (2000rpm) US.................$14,800

NEO Automatic Vertical / Horizontal Head 3500rpm US..$44,800

CNC Boring + Facing Head ZX300-TC US.................$64,800

Fagor 8065 Control with 15" High resolution color LCD monitor.

Table: 59" x 49.21"(1500x1250mm)

13200Lbs loading capacity for 0.001° positioning

11000Lbs loading capacity with B axis cutting feed function

Servo driver 0.001°, full CNC Simultaneously controlled continuous rotary table.

X/Y/Z/W Travel:80"/72"/56"/20" (2000/1800/1400/500mm)

Solid one piece casting base instead of out-bound supports

2 speed, high torque ZF planetary gearbox on spindle for heavy duty work at low speed

2500 rpm spindle with ISO#50 taper

Linear Scales on X/Y/Z axis and angle encoder on B axis for absolute positioning accuracy

4-roller liner guard way on Z axis

Hardened and ground guide ways on Y axis allows max torque on the spindle

Full enclosure flash guard with working station

60 position ATC mounted on machine to avoid any misalignment

12" Spindle sleeve as standard accessory

300PSI Through spindle coolant and guard system for CTS

Heavy duty telescopic way cover for sub-supporter guide ways

Chip conveyor combine with Chip auger for maximum chip handling

Optional Equipment:

Manual 90 Degrees Milling Head (2000rpm) ($14,800.00)

Automatic Vertical / Horizontal Head 3500rpm ($44,800.00)

CNC Boring + Facing Head ZX420-TC ($68.800.00)

Max boring diameter:770mm ( 30.315â€)

Max facing diameter: 980mm ( 38.583â€)

Boring slide travel:102mm ( 4.016†)

Perform accurate lathe-type operations on horizontal boring mills

Maximum application flexibility

Machine diameters, faces, tapers,radii, and profiles

High material removal rates

High quality for long working life

Extremely rigid and durable design

Backlash-free operation

Examples of internal configurations machined using ZX contouring head system.

Part geometries shown below are commonly found in parts such as oil valves and blowout preventers, gearboxes, pump housings, compressors, engine housings, aerospace and power generation components, large castings, and heavy equipment components.

We use cookies to improve your experience. Privacy Policy.