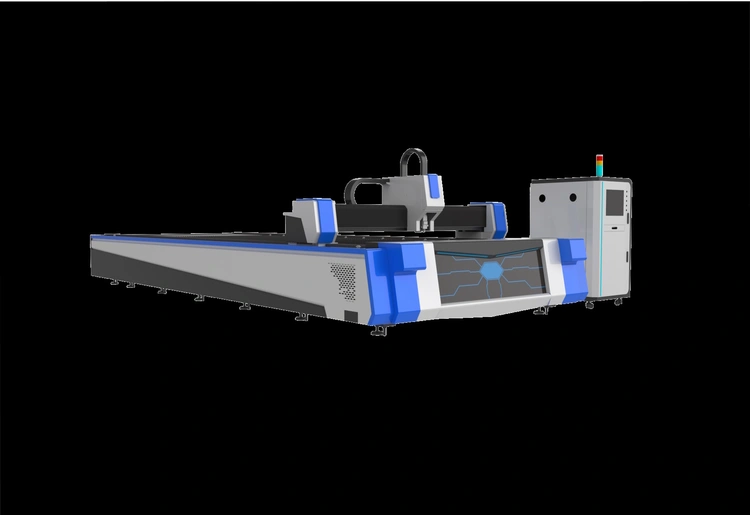

Senfeng Model SF-4020 G Laser With 6'X13' Table

SF4020G Fiber Laser Cutting Machine Sheet Metal Cutting System

Table Size:6’×13’

Max Laser Source, 6kW

Raytools Auto Focus Cutting Head

6Kw Water Chiller

Transformer-Laser wired for 380V-3Phase.

Operational Software FSCUT 2000

Nesting Software CYPCUT

2 Year Warranty

(Everything Except Consumables) (Customer's responsibility to offload machine from delivery truck and put at the proper location)

(Customer's responsibility to get the proper power for machine according to local standards)

Onsite Installation Onsite Training

(Training 2-3 days at customer shop)

Work area (Length X Width)....................6’x 13’

Maximum load..................................2,755lbs.

X-axis travel.................................79”

Y-axis travel.................................159”

Z-axis travel.................................8”

X/Y-axis positioning accuracy.................±0.05mm/0.001”

X/Y-axis repeated positioning accuracy........±0.02mm/0.0007”

Maximum speed.................................100m/min/3,937”/min

Maximum acceleration..........................1.0G

Weight........................................11,464lbs.

Maximum load..................................2,755lbs.

Dimensions (length x width)...................R-L 233”x F-B 123”

Height........................................82"

Phase........................................Three phase

Rated voltage of power supply................380V

Frequency....................................50Hz

Power supply protection grade................IP54

6000W laser source...........................Max

Laser cutting head...........................Senfeng TYRFING

Machine tool · host

Transmission system..........................Taiwan LAPPING/Senfeng

Machine tool and accessories.................Senfeng

Reducer......................................France MOTOREDUCER

Electrical and pneumatic systems.............France SCHNEIDER

.............................................Japan SMC & Taiwan AIRTAC

AC servo motor and driver....................Taiwan DELTA/France SCHNEIDER

Water chiller................................HANLI

CNC control system...........................Senfeng Mimir LS3000

Materials......Thickness......Cutting Speed......Gas

Stainless Steel

...............0.0393.........45-55..............N2/Air

...............0.0787.........30-35..............N2/Air

...............0.1181.........18-22..............N2/Air

...............0.1574.........10-14..............N2/Air

...............0.1968.........8.0-10.............N2/Air

...............0.2356.........4.3-5.0............N2/Air

...............0.3149.........3.0-4.0............N2/Air

...............0.3937.........1.8-2.5............N2/Air

...............0.4724.........1.0-1.5............N2/Air

...............0.5511.........0.8-1.2............N2/Air

...............0.6299.........0.6-1.0............N2/Air

...............0.7874.........0.4-0.7............N2/Air

Carbon Steel

...............0.0393.........40-45..............N2/Air

...............0.0787.........20-28..............N2/Air

...............0.1181.........12-17..............N2/Air

...............0.1574.........8.0-10.............N2/Air

...............0.2356.........2.5-3.3............O2

...............0.3149.........2.3-3.0............O2

...............0.3937.........2.0-2.5............O2

...............0.4724.........1.8-2.2............O2

...............0.5511.........1.4-1.7............O2

...............0.6299.........1.0-1.6............O2

...............0.7874.........0.6-1.2............02

...............0.9842.........0.5-0.7............O2

...............1.1811.........0.4-0.6............O2

Brass

...............0.0393.........40-45..............N2/Air

...............0.0787.........20-25..............N2/Air

...............0.1181.........12-15..............N2/Air

...............0.1968.........5.0-6.0............N2/Air

...............0.2356.........3.0-4.0............N2/Air

...............0.3149.........1.5-2.5............N2/Air

...............0.3937.........1.0-1.5............N2/Air

...............0.4724.........0.8-1.0............N2/Air

Aluminum

...............0.0393.........50-55..............N2/Air

...............0.0787.........25-30..............N2/Air

...............0.1181.........13-16..............N2/Air

...............0.1574.........10-13..............N2/Air

...............0.2356.........3.0-4.0............N2/Air

...............0.3149.........2.0-3.0............N2/Air

...............0.3937.........1.0-2.0............N2/Air

...............0.4724.........0.7-1.2............N2/Air

...............0.6299.........0.5-1.0............N2/Air

...............0.7874.........0.4-0.6............N2/Air

Advantage Laser Cutting

Items..................Plasma..........Laser.............Laser Advantages

Positioning accuracy...0.4 mm..........0.14 mm...........High Precision

(especially 10m bed)

Section taper..........5MM.............0.4...............No need for fine processing

(especially 40mm thick)

Kerf...................4-6.0mm.........0.2-1.6 mm........Save 6-9% of materials

Bleed and co-edge......10 mm...........3-4.mm............Save 6-9% of materials

Heat affected zone.....0.5-2.0 mm......0.1-0.4 mm........Less heat absorption,

.........................................................less deformation

Cutting effect.........Average.........Excellent,........No need for sanding

.......................................less slags

Cutting speed..........Average.........Very fast.........High production efficiency

Piercing..............Can't cut........Diameter-depth

......................small holes......ratio of 10-20%...Save drilling and handling

Working environment...Smokey...........Clean.............Healthy and environmentally

.........................................................friendly

We use cookies to improve your experience. Privacy Policy.