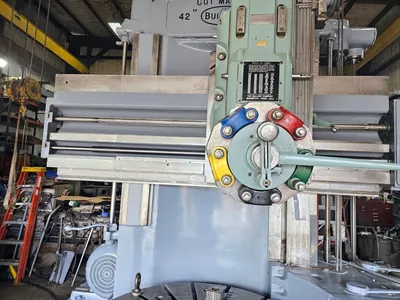

42" Used Bullard (Cut Master) Vertical Turret Lathe Model 42

Table Size..............................................42" 4-Jaw

Swing Side Head Above Table.............................45"

Swing Side Head Below Table.............................54"

Cross Rail Travel.......................................25"

Height Under Rail.......................................37"

Cross Rail Traval Up And Down...........................26"

Table Speed.............................................4.1 To 150 Rpm's

Floor To Chuck..........................................36"

Turret Head Travel Left To Right........................26-3/8"

Turret Head Swivel......................................30 Degrees

Turret Head Turret Travel Up & Down.....................30-3/8"

Max. Distance Table To Turret Face......................48-1/4"

Turret Head Position....................................5

Turret Hole Diameter....................................2-3/4"

Turret Head Feeds.......................................0.026 To 500 IPR

Side Head Travel In & Out...............................21"

Side Head Travel Up & Down..............................37"

Side Head Feeds.........................................0.026 To 500 IPR

Main Motor..............................................30 Hp.

Max. Overall Height Rail and Heads In Highest Position..145"

Machine Floor Space.....................................R-L 131.5" X F-B 104"

Machine Height..........................................9'8"

Weight..................................................42,500 Lbs.

Power Elevation Of Rail.................................Yes

Rapid Traverse To Both Head.............................Yes

Built In 4 Way Tool Post On Side Head...................Yes

Turret Head.............................................Yes

Note:

Note: Reconditioning:

Machine Has Been Cleaned, Painted And Cycled.

1. Turret Slide & Swivel in our facility. Dismantle unit as required.

Clean all component parts.

2. Re-machine all bearing surfaces of the Turret Slide to remove localized wear.

3. Re-machine all bearing surfaces of the Turret Swivel to accept Turcite Way

material.

4. Install Turcite to the Swivel and machine to correct height to compensate for

material removed from Turret Slide.

5. Machine or grind oil grooves into swivel material for proper delivery of lubrication

oil.

6. Block and hook frost all bearing surfaces of the turret slide for "pockets" for

retention of lubrication oil.

7. Precision scrape and fit turret slide to swivel for proper bearing fit.

8. Manufacture new meehanite cast iron gibs for turret slide. Oil groove for proper

delivery of lubrication oil.

Precision scrape and fit allowing full range of adjustment to compensate for any

future wear.

These gibs will be the earless type.

9. Install triple lead down-feed screw and nuts. Install into nut body and realign to

assure smooth and accurate operation.

10. Hang turret assembly in vertical position and reset turret locking mechanism for

proper operation.

Reset backlash eliminator to proper setting.

11. Cross-rail screws and nut will be replaced.

12. Turret and ram vertical screws and nuts replaced.

13. All feed and rapid shafts seals will be replaced. Hand wheel seals will be

replaced; gear boxes will be cleaned and checked.

Hydraulics and main motor have been reconditioned.

Machine should be ready to ship in about 36 to 48 weeks after receipt of PO and

down payment.

Optional:

42" 3-Jaw With Hard Top Jaws $19,500.00

We use cookies to improve your experience. Privacy Policy.