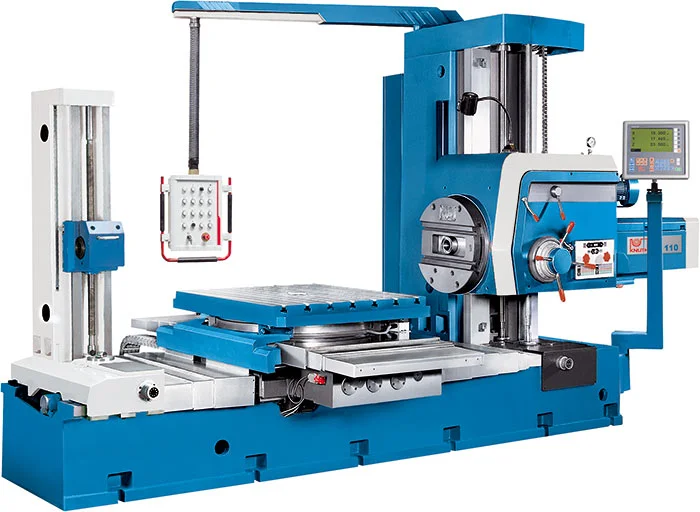

New Knuth 4" Horizontal Boring Mill Model BO 110

The BO series of conventional boring-milling machines is designed for horizontal, multi-sided drilling and milling of workpiece weights of up to 2.5 tons. The stand is fixed, while the table can move and rotate 360°. The drill head moves on the column and the spindle has a long stroke on the W-axis. Conventional boring mills also have a facing slide with a long stroke, which extends the application to include boring. High drive power and automatic feeds on all axes with rapid traverse enable efficient machining and short non-productive times.

Large work area with W-axis and facing slide

Thread cutting unit

Setup table rotates 360°

Telescoping stainless steel covers on all guides

Tailstock included

SPECIFICATIONS

Drilling capacity.......................................2"

Travel X-axis...........................................35"

Travel Y-axis...........................................35"

Travel z-axis...........................................24"

Travel W-axis...........................................39"

Facing slide travel.....................................7"

Table set up area.......................................43"x38"

Table load capacity.....................................5,500 lbs.

Spindle axis-to-table surface distance..................O - 35"

Rotation speed of rotary table..........................1 rpm

Headstock

Spindle diameter........................................4"

Spindle mount ISO.......................................50

Speed range (22)........................................8 - 1,000 rpm

Headstock torque........................................903 ft/lbs.

Feed force, axial (max.)................................12 kN

Facing slide speed (18).................................4 - 200 rpm

Facing slide torque (max.)..............................1,445 ft/lbs.

FEED

Facing slide feed.......................................0.003 in/min - 0.472 in/min

Feed X-axis-Steps 36

Feed X-axis.............................................0.00039 in/R - 0.23622 in/R

Feed Z-axis-Steps 36

Feed Z-axis.............................................0.00039 in/R - 0.23622 in/R

Feed Y-axis-Steps 36

Feed Y-axis.............................................0.00039 in/R - 0.23622 in/R

Feed W-axis-Steps 36

Feed W-axis.............................................0.00039 in/R - 0.23622 in/R

Facing slide feed-Steps 18

RAPID FEED

Rapid feed X-axis.......................................98.43 in/min

Rapid feed Y-axis.......................................98.43 in/min

Rapid feed W-axis.......................................98 in/min

Accuracies

Read-out accuracy (optic)...............................0.0004"

Counter-bore accuracy H7 Ra-............................1,6 µm

Drive Capacity

Motor rating main drive.................................10 Hp.

Motor rating servo drive................................4 Hp.

Motor rating for Z-axis drive...........................5.4 Hp.

Motor rating hydraulic pump.............................1 Hp.

Measures and Weights

Overall dimensions......................................192"x97"x108"

Weight..................................................25,300 lbs.

Standard Equipment

3-axis position indicator

Tailstock

Alignment wedges

Central lubrication

Work lamp

Foundation bolts

Operating tools

Operator manual

BO 110 Horizontal Drilling/Milling Unit 460V, 3Ph, 60Hz.

Heavy drilling and milling unit for machining large and heavy work pieces

• Rigid, hardened and precision-ground square guides ensure many years of

accurate operation

• Mechanical functions that may not be run simultaneously are provided with

interlocks

• Headstock and feed gears are equipped with an overload clutch

• Lever-operated shift gears for positioning of the wheels in the desired position

• Faceplate and drill spindle with different task-specific speed ranges according

to the various functions

• Table rotates 360° and tailstock included

• Telescoping steel cover protects the guides from chips and dirt

• 3-axis position indicator

8822 $16,600.00

Installation verification and machine operation training (2 KNUTH technicians,

5 business days on site) includes KNUTH technician's labor from 8am-5pm

(Monday-Friday), transportation, local travel, meals and lodging.

8815

Warranty: Standard (12) months new machine warranty, one shift operation

(2,000 hours).

Covers parts, labor, and domestic travel, except for special offers.

The customer is responsible for any freight and all other associated costs

not covered by warranty.

Warranty commences upon delivery of machine. Consumables and operator

misuse are excluded. Any damage to machine as a result from incorrect setup,

misuse, negligence, poor maintenance, or other circumstances beyond our control

is not covered under warranty.

Note: Prices Subject to change without notice.

Delivery 9 months after receipt on Purchase Order and Down Payment.

KNUTH Machine Tools USA - your partner for metal working machinery since 1923!

KNUTH USA is the North American Headquarters of the KNUTH Group located near Hamburg, Germany. The KNUTH Group currently has sales, service, and production facilities in more than 35 countries.

We at KNUTH believe that the productivity of your machines determines the cost per part and ultimately the competitiveness of our customers. The most productive machine is only as good as its uptime. That's why we have developed the industry's leading Customer Service and Support Guarantee:

Technical Phone Support

We have developed a system that assures you a call back during hours of operation from one of our technical engineers within 30 minutes, provided at no charge for the lifetime of the machine - guaranteed.

Technical Onsite Support

Our service engineers participate in a rigorous training program and are subject to high quality standards. If you need assistance with your machine, we are happy to come on site and solve the problem - guaranteed.

Besides onsite troubleshooting our service team also offers the following services:

- Machine installation and set up

- Emergency repair service

- Preventative maintenance programs

- Machinery relocation support

- Operator and maintenance training, either at the customer facility or at KNUTH USA

- Application based problem solutions

Spare Parts

In our centrally located facility in Chicago, IL we offer more than 6,000 parts that can be shipped the same day. Additionally, our internal global KNUTH spare parts network allows us to access more than 35,000 parts that are ready to ship within 48 hours - guaranteed.

Quick Set Up Time

All of our machines get completely inspected under production conditions in our test center prior to ship. This includes a full electrical and mechanical testing of more than 40 inspection points. All machines are completely cleaned and shop ready. We are proud to have the quickest set up time - guaranteed.

Price Clause

The above prices for the equipment are understood to be FOB KNUTH Machine Tools USA, Inc. (590 Bond Street, Lincolnshire, Illinois, USA). Excluded are your local and state taxes. The above prices are valid for 30 days from the date of this quotation. Taxes are not included, except for sales in the state of Illinois, and will be the responsibility of the customer.

Delivery of Equipment

Freight charges from KNUTH USA will be the responsibility of the customer. Customer is responsible for unloading machine

at destination.

Commercial

The above prices are in US dollars and are valid for thirty days.

Payment Terms

Standard payment terms are as follows:

All payments to be made to KNUTH Machine Tools USA, Inc:

a) 30% deposit on all orders

b) 70% net prior to shipment

Special order machines may require an additional progress payment. Please refer to your quotation. Payment terms are available upon credit approval. Please contact your salesperson for more information.

Credit card payments are acceptable on all purchases. A convenience fee of 3.5% will be applied to all credit card transactions above $ 5,000.

Warranty

Standard (12) months new machine warranty, one shift operation (2,000 hrs). Machines below $30,000, covers parts only. Machines above $30,000, covers parts and labor. Machines above $60,000, covers parts, labor, and domestic travel, except for special offers. The customer is responsible for any freight and all other associated costs not covered by warranty.

Warranty commences upon delivery of machine. Consumables and operator misuse are excluded. Any damage to machine as a result from incorrect setup, misuse, negligence, poor maintenance, or other circumstances beyond our control is not covered under warranty.

Point of Operation Guarding

While some machines are provided with guards, it is the responsibility of the customer to provide point of operation guarding.

Services

Customer is responsible to supply the required services to the machine:

- Electrical Power

- Air supply

- Water, Fluids, and Gasses

Documentation

All Operation/Maintenance manuals, schematics, labels and documentation are written in English.

Exclusions

KNUTH Machine Tools USA, Inc. is not liable for loss of production due to down time or any unanticipated problems with machine configuration, operation, or installation.

Additional Services

Installation and training services are not included. KNUTH Technicians can provide these services at an additional cost.

Please contact your sales representative. The machine(s) will be fixed on a wooden or steel pallet or just beams, protected against rust with grease and covered with stretch foil. For additional packaging, which includes a frame or wooden box (required when shipping by common carrier, non-flat bed transportation), we charge 2.5% of the machine price.

Thank you for the opportunity to present this proposal. We look forward to your valued order!

We use cookies to improve your experience. Privacy Policy.