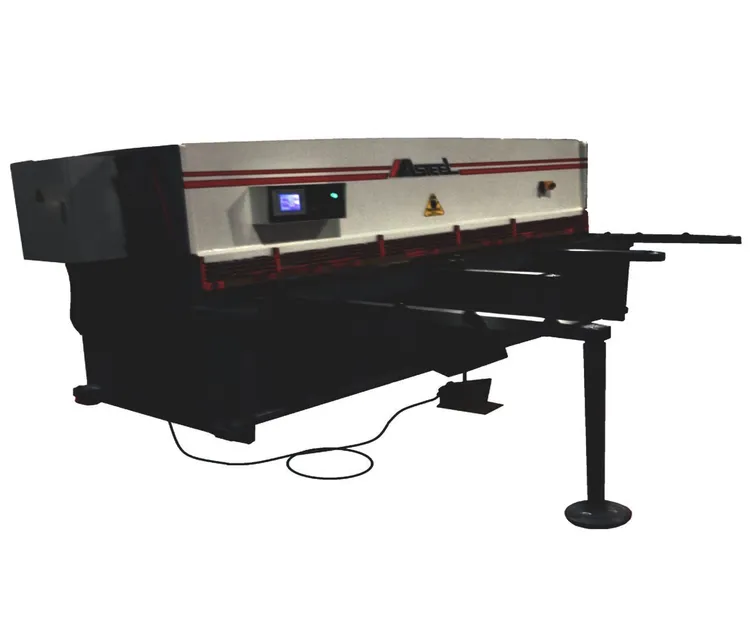

New 10' X 1/2" Masteel CNC Hydraulic Shear

Rated Capacity Mild Steel 1/2"

Cutting Length 10'6"

Throat Depth 8"

Back Gauge 36"

Front Gauge 48"

Rake Angle 1 Degree 30'

Dimensions Length & Width 160" X 82"

Machine Height 84"

Weight 29,500 Lbs.

Main Motor 25 Hp.

Options Price (USD)

Rear Sheet Support $10,760.00

High Speed Hydraulic Package(Increase Speed by 1.6)

1⁄4’’ 10’ Shear 15 Full Strokes Per Min to 24 Full Strokes Per Min$2,190.00

1⁄2’’ 10’ Shear 12 Full Strokes Per Min to 19 Full Strokes Per Min$2,880.00

CNC In-Feed Table $18,730.00

39’’ Back Gauge $1,730.00

575 Volt 3 Phase $1,020.00

Auto Blade Gap Adjustment $2,880.00

Accuracy

Top blade and back gauge with swing movement always have the

cutting perpendicular to the material and bottom blade, then

swing away from bottom blade.There is no jamming the material

between the blades and back gauge. Top and down blade last

longer to ensure quality cutting and less maintenace.

Reliability and Functionality

Masteel Swing bean shear doesn't require relieve angle. The cutting

is always perpendicular to the material and bottom blade.

And also the hydraulic force from the cutting cylinder is applied

directly against cutting load. There is no cutting load to change

the blade clearance from blade deflection or blade beam

mechanism. That allows Masteel shears cut strips.

Quality and Heavy-Duty Structures

Mono-block type, welded frame and blade beam are optimized

by computer-aided calculation to guarantee the maximum rigidity.

Heavy-duty taper roller bearings are located on cutting lever and

support blade beam rotational movement.

It avoids cutting load transferred along blade beam rotational radius

to the supporting bearings to ensure constant accurate blade clearance.

Quality Components and Structure Design

North-American made hydraulic & electrical system.

Standard SIEMENS single-axis CNC controller.

Swing beam design for consistent precise

cutting quality and low maintenances.

Simple hydraulic and electric system for easy service.

Low rake cutting angle for minimum distortion of material: 1 30’ on 1/4’’, 3/8’’,

1/2’’ shears.

Heavy duty design, rigid stress relieved box construction.

Standard Control Features:

36” SIEMENS multi-step CNC back gauge: accuracy at ±0.002”.

60 position pre-set back gauge memory for shearing heavy material or production

process with no need of layout or holding material, then adjusting back gauge.

One-step go-to position control on back gauge.

Auto-swing up back gauge at full travel.

Programmable cutting width control.

Programmable cutting stroke control.

Easy operating control console:

Prompting instruction for easy operation and service

Running status display on control console

Manual/Auto model Back gauge position

Cutting width

Number of cutting strokes

Blade setup message at power on to prompt operator

Movable Pedestal with Foot Control Switch and Emergency Stop

SIEMENS Compact Control System:

SIEMENS compact control system integrates CNC back gauge,

hydraulic and electronic control in one.

Simple and less control components ensure years of quality performance

of Masteel shears.

Operating Function:

Rapid precision blade clearance adjustment.

Steady cutting speed and rapid back stroke for high efficient performance.

Multi-control mode:

Pushbutton / Foot switch operation.

Single cut/ continue cuts mode.

Multi-back gauge position and multi-cuts automatic control mode.

Auto clamping pressure control on hold down feet auto-adjustable to various material.

Complete hydraulic, electric overload protection avoids operating fault.

Standard Equipment:

Two square arms with stainless steel rules and disappearing stops:

7 Ft squaring arm on left to square long sheet material.

4 Ft squaring arm on right to provide even knife service life on both ends

Front gauge with adjustable disappearing stops and stainless steel rules:

4 Ft front support arms

Ball transfers in table for easily handling heavy metal

Ball transfers on front support arms, front gauge bar and right squaring arm

Shadow light and line for positioning scribed line

Cut-off material sliding tray for easy-collecting cutting material

Safety guard.

Independent Hold-Downs

Automatically adjust hold-down pressure to various material.

More hold-down pressure for heavier cutting and less for

delicate thin material.

Blade Adjustment

Precision variable position quick blade

adjustment ensures proper blade clearance for

various material thickness and properties and

achieve quality cutting.

36’’ CNC Back Gauge

Slide tray for easy collect of cut-off strips.

Heavy-duty structure.

Precision leadscrew with integrated backlash compensation.

Back gauge bar swings up at full travel to allow long material

to go through.

Terms and Conditions

Price:

Prices are Net. All prices are quoted in Canadian DOLLARS Unless otherwise noted.

Due to constant fluctuations in Currency Exchange rates, Prices may change without

notice and prices published may not be current for incoming stock. All taxes extra

Terms: 50% deposit balance due prior to delivery

Delivery: TBA

FOB: To be advised

Warranty: NEW EQUIPMENT: 1 year Parts & Labour. travel & accommodations extra cost.

All electrics warranted by manufacturer. All parts are FOB Vancouver unless otherwise specified. All

shipments are by ground transport. Fuses, wipers, and other normal wear items are not covered under

this warranty.

NOTE: All specifications are approximate, and are not binding in any way. We endeavour to

make information as complete and accurate as possible. If you notice a discrepancy, please

let one our sales people know so that the error can be changed.

We use cookies to improve your experience. Privacy Policy.